Introduction

In optical setups, the in-line polarizer is a crucial but often overlooked component. It plays a vital role in controlling the polarization state of light passing through it. Selecting the appropriate in-line polarizer is essential for optimal performance and accurate results in various optical applications. This guide explores key factors to consider when choosing the right in-line polarizer for your specific setup.

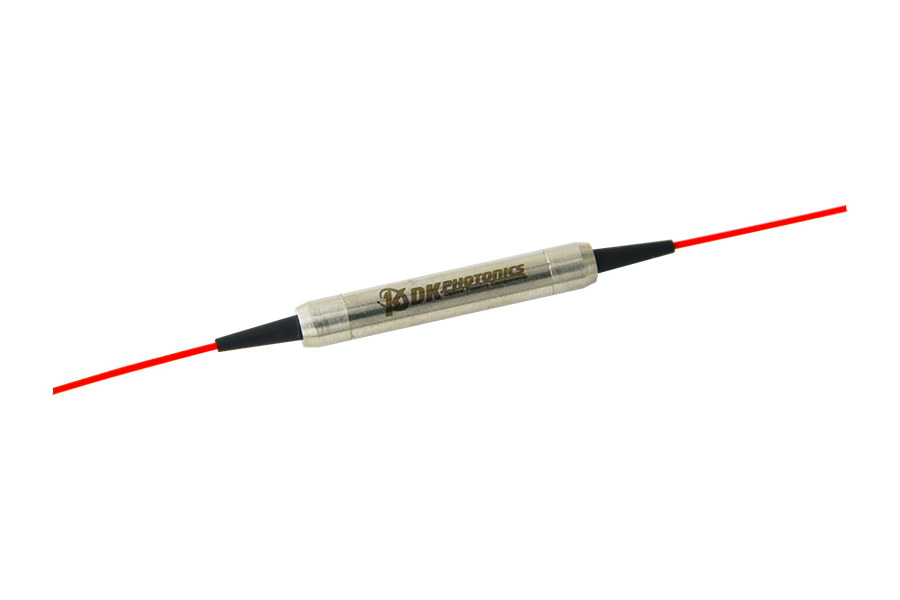

Understanding In-line Polarizers

In-line polarizers selectively allow light with a specific polarization state to pass through while blocking others. Widely used in applications like microscopy, spectroscopy, laser systems, and telecommunications, these optical components significantly impact the quality and accuracy of measurements and experiments.

Polarization Techniques in Optical Setups

- Polarization by Absorption: Achieved through absorption polarizers that selectively absorb one polarization state.

- Polarization by Transmission: Utilizes birefringent materials to separate polarizations based on their different refractive indices.

- Polarization by Reflection: Reflective polarizers polarize light through reflection, suitable for scenarios where transmission-based polarizers are not ideal.

Selecting the Suitable Polarizer Material

Various materials, each with unique advantages and limitations, are used to construct in-line polarizers. Examples include Polaroid sheets, Calcite crystals, and Liquid Crystals.

Considering Polarizer Efficiency

Efficiency is critical when choosing an in-line polarizer.

- High Extinction Ratio: Ideal polarizers should have a high extinction ratio to efficiently block unwanted polarization states.

- Broadband Operation: For applications across a wide wavelength range, choosing a broadband polarizer is essential for consistent performance.

- Angular Field of View: The polarizer’s angular field of view is crucial in setups with different incident angles.

Dealing with Polarizer Temperature Dependence

Selecting a polarizer that can withstand varying operating temperatures is essential.

- Polarizers for Low Temperature Applications: Specialized polarizers with low-temperature dependencies are required for cryogenic experiments.

- Polarizers for High Temperature Applications: Polarizers with high-temperature stability are necessary for setups operating in high-temperature environments.

Mounting and Alignment Considerations

Proper mounting and alignment are crucial for effective polarizer functioning.

- Optical Axis Alignment: Aligning the polarizer’s optical axis with other components minimizes losses and maximizes performance.

- Beam Deviation and Shift: Careful mounting is essential to avoid beam deviation or unwanted shifts.

Integrating Polarizers with Other Optical Components

In some setups, integrating polarizers with other optical components can yield desirable results.

- Polarizer-Analyzer Pair: Combining a polarizer with an analyzer allows precise control over the polarization state of light.

- Polarizer-Waveplate Combination: Integrating a polarizer with a waveplate helps achieve specific polarization states required for experiments.

Ensuring Compatibility with Optical Setup

Compatibility with the existing optical setup is crucial for seamless integration.

- Wavelength Compatibility: Ensure the polarizer’s wavelength range aligns with the light sources used.

- Power Handling Capacity: For high-power laser systems, the polarizer should have sufficient power handling capacity.

Evaluating Cost and Budget Constraints

While performance is crucial, it’s also important to consider budget and cost constraints.

Maintenance and Lifespan of In-line Polarizers

To ensure longevity and optimal performance, proper maintenance is necessary.

- Cleaning and Handling: Follow manufacturer guidelines for cleaning and handling to avoid damage.

- Expected Lifespan: Understand the expected lifespan of the polarizer to plan for replacements or maintenance.

Troubleshooting Polarizer Issues

Despite careful selection, issues with polarizers may arise over time.

- Polarizer Degradation: Identify signs of polarizer degradation and know when it’s time for a replacement.

- Polarizer Misalignment: Troubleshoot misalignment to avoid performance issues.

- Compatibility Problems: Address compatibility issues with other optical components and find suitable solutions.

Conclusion

Selecting the right in-line polarizer is critical for achieving accurate and reliable results in optical setups. Consider polarization technique, polarizer material, efficiency, temperature dependence, mounting, integration with other components, compatibility, and budget constraints. By making an informed decision and ensuring proper maintenance, you can optimize the performance and lifespan of your optical setup.

Leave A Comment