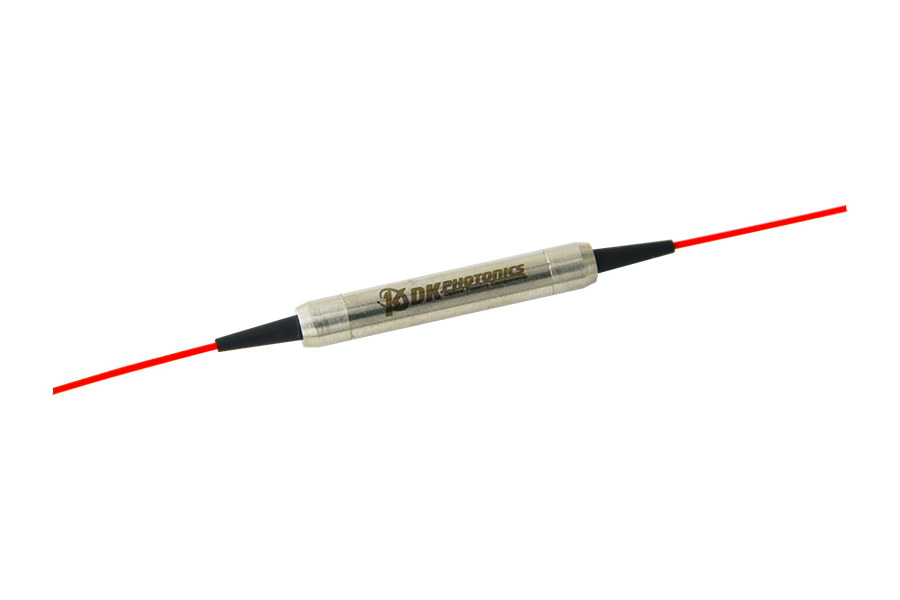

The small pieces of cable in fibers that are capable of polarizing the incoming light signals are known as in-line polarizers. The reason why these devices are known as in-line polarizers is that they are positioned in-line with the fiber. With the help of this, fiber can produce output signals with optimum intensity and bandwidth without causing any hindrance in velocity.

In-line polarizers are used in different applications and they truly give good results. But some questions are unanswered about these devices, so people or organizations are resistant to using the same. They think devices won’t be useful for them or the investment won’t be worth it.

In this post, we will discuss some common questions related to in-line polarizers.

What’s the difference between pigtail and no-tail polarizers?

Pigtail in-line polarizers come with attached input/output fibers to the package. These polarizers are mostly used for fiber systems that require optical components spliced to the networks or extra fiber to fill the gap between lengths. The pigtail in-line polarizers provide a great level of flexibility when mounting and installing the device. The typical length of the pigtail polarizer is 1 to 2 meters on each side.

Regarding no-tail in-polarizers, they come with two fiber connectors mounted straight on the package. These polarizers are preferably used for applications where there is no need for extra fiber length and several fiber jumpers/connections are already in the system.

Why should you use small-sized in-line polarizers?

In-line polarizers are available in different sizes, based on the applications they are used for. But, preferably, smaller in-line polarizers are used in different applications by organizations. And it’s because of the space constraints. Smaller in-line polarizers can adjust everywhere and anywhere, making operations easy. Other than this, these polarizers come with lower insertion loss.

What’s the standard cost of in-line polarizers?

Investing in polarizers is a big thing for an organization and its capital. So, considering the cost of in-line polarizers is important. Truly speaking, there is no such standard cost of in-line polarizers.

The cost of in-line polarizers depends on their structure. The polarizers that come with large, very pure crystals are expensive while the polarizers made up of stretched plastic are a bit affordable. The choice depends on the scope of work.

What will happen if the extinction ratio (ER) is poor?

Extinction ratio or ER is the ratio of transmission of desired polarization to undesired polarization. In other words, it is defined as the ratio of two optical power levels of the digital signal. Basically, the extinction ratio is expressed by a fraction, dB, or percentage.

If the value of extinction value is poor, it will lead to an increase in Power Penalty or PP. Also, a poor extinction ratio worsens Bit-Error-Ratio (BER) and reduces the benefit of increased power. So, it’s always said to choose in-line polarizers with a high extinction ratio.

We hope you got the answers to some unanswered questions related to in-line polarizers. So, connect with DK Photonics and get in-line polarizers today.

Leave A Comment