For data transmission and light guiding applications, fiber optic cables are commonly used. They are extremely efficient for transmitting data over long distances at a wide bandwidth. Because of this, fiber technology is applied in different industries.

Through optical fibers, both polarized and unpolarized can travel. But, there are problems with unpolarized light traveling. It travels with significant losses and distortions over large distances, which cause harm to the transmission of information through optical networks.

Different solutions were found for this problem. But, the one that actually worked and gave good results was the in-line polarizer. This provides the strongest and cleanest output signal.

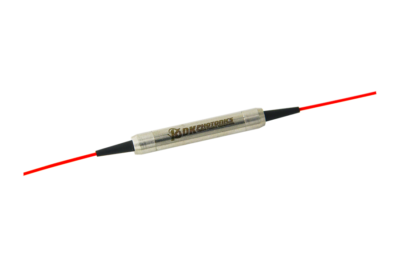

The in-line polarizer is a device that passes light with one specific polarization and blocks the other polarization. There is a conversion of unpolarized light into polarized light with maximum intensity and bandwidth without hindering velocity. You can refer to it as a high extinction ratio.

Types or versions of the in-line polarizer

Pigtailed in-line polarizer- It comes with 1 to 2 meters fibers pigtails on each side. In this, you will find that input-output fibers are attached to the package. Typically, the pigtailed in-line polarizer is used for fiber systems that require optical components spliced to the networks or extra fiber to fill the gap between the lengths. One major benefit provided by this polarizer is a great level of flexibility in device mounting and installation. The best thing is it is economical.

No tail in-line polarizer– Unlike pigtailed in-line polarizers, the no tail in-line polarizer comes with two fiber connectors mounted straight on the package. If you don’t need to add extra fiber length and several jumpers/connections are already available in the system, you should use no tail in-line polarizer. With no pigtails, handling the polarizer becomes easier. Also, it gives the benefit of removing the polarization disturbance that is caused by pigtails.

Are all in-line polarizers the same?

In the world, different optical passive components manufacturers manufacture in-line polarizers. Though the objective of the product is the same, some features are different because it is manufactured by different manufacturers. Or, the different features are required for different industries and different purposes.

If you are going to purchase an in-line polarizer, consider the following points:

First, look for a reputable manufacturer. Make sure the manufacturer has enough experience in the industry and is a new entrant. Read the details and clear all your doubts before making the purchase.

Other factors to consider are:

Insertion loss– The polarizer you choose should minimize the resultant loss caused after inserting it into the system.

Bandwidth– For different applications in different industries, different bandwidths are used. So, you should choose an in-line polarizer that matches the desired output bandwidth. You should know the bandwidth requirement before making the selection.

Size– Just like bandwidth, the size requirements are different for the systems in which the in-line polarizer will get inserted. Many systems are fine with smaller polarizers because of space issues. But, the other systems require larger polarizers.

An in-line polarizer is important for data application and other related applications. So, choose wisely.

Leave A Comment