Fiber lasers are now widely used in industry, science, and medicine, where very strong laser beams are needed. Engineers have found ways to make fiber lasers that can output more and more power. But running lasers at such high power can cause some issues. One key part that helps deal with those issues is called a cladding power stripper. This article explains what this is and how cladding power strippers help high-power fiber lasers work well and safely.

The Role of Cladding in Fiber Lasers

In a fiber laser, the core is the point in the glass fiber that guides the laser beam. Surrounding the core is a larger glass layer called the cladding. The cladding helps visually contain and guide the light waves in the core. As the laser light travels down the fiber, its lower refractive index causes it to be reflected into the higher index core.

Many high-power fiber lasers use a double-clad structure. That means there is an inner cladding layer close to the core and a larger outer cladding layer surrounding that inner cladding. This double-clad design helps confine the light and handle higher power levels.

Why Unused Cladding Power Needs Stripping

In a high-power double-clad fiber laser, intense pump light from laser diodes enters through the outer cladding layer. As it travels down the fiber, this pump light stimulates the gain medium in the core, creating a population shift that enables lasing action.

However, not all of the pump light gets fully absorbed as it passes through. Some of the residual unused pump light can reflect at angles and continue traveling in the inner cladding layer. This unused cladding light is wasted energy that can cause unwanted effects like heating. It can also damage optical components that are further downstream.

Cladding Power Strippers Absorb and Remove Residual Light

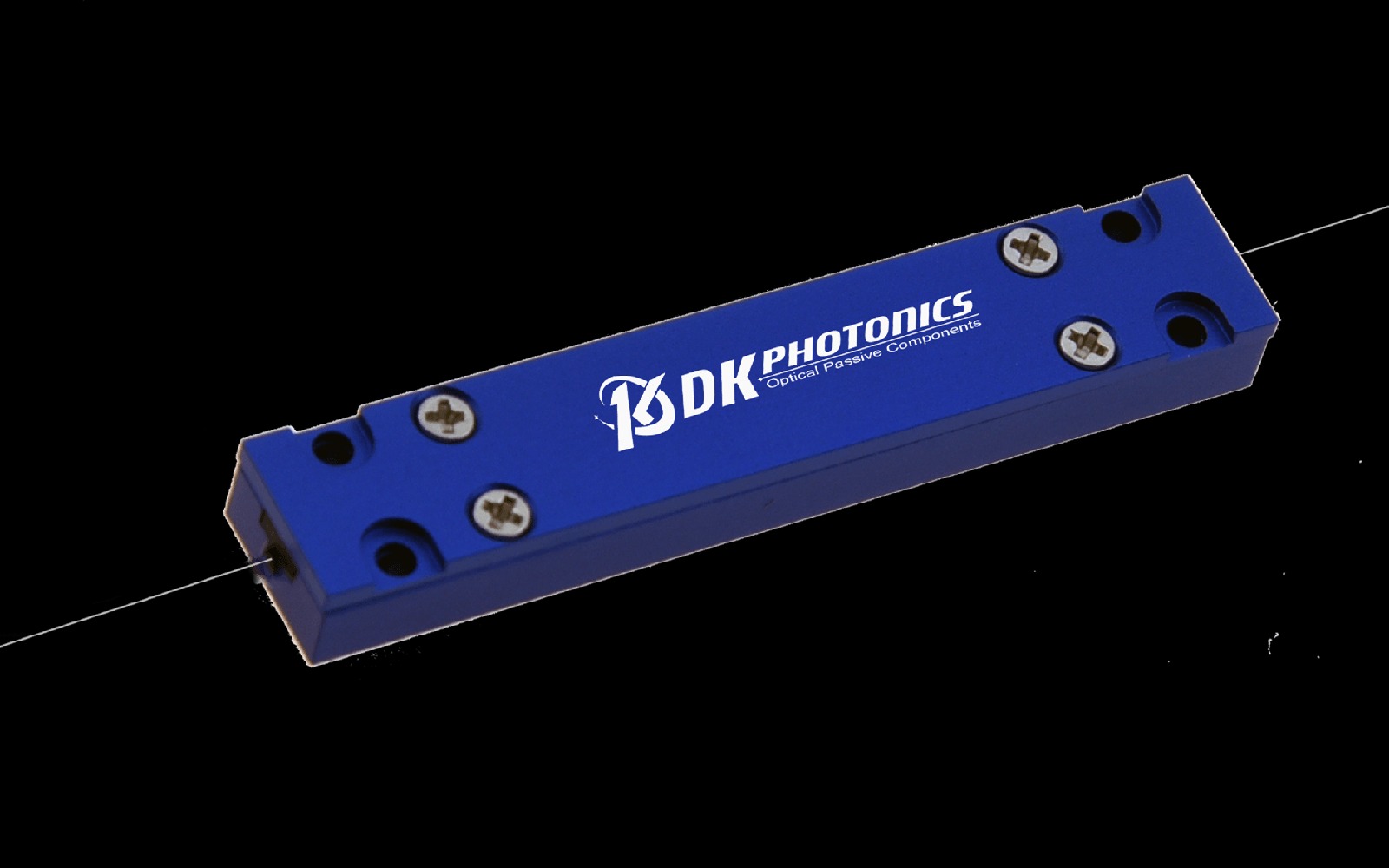

A cladding power stripper provides an efficient solution to absorbing and removing this residual unused pump light in the inner cladding. It is attached to the end of the fiber laser cavity to “strip out” the wasted cladding light before it exits.

The key part of the cladding power stripper is a section of passive fiber that has an absorbing polymer coating applied to the cladding area. As the residual pump light travels through this coated fiber section, it gets absorbed by the polymer. This absorption effectively strips away the unused power.

Key Benefits and Applications

Cladding power strippers offer several important benefits:

- They prevent further damage by eliminating unused pump lights that would otherwise exit the cavity. This improves component reliability.

- They allow fiber lasers to operate at higher pump powers and extraction efficiencies since unused light is cleaned up.

- Their ability to absorb excess cladding power improves laser stability and efficiency.

Cladding power strippers are highly customizable for different fiber types and power handling capacities:

- They can handle cladding power levels up to 500W or more.

- They exhibit low insertion loss and excellent power handling ability.

- They provide high stability, even at high temperatures.

- They are available in polarization maintaining (PM) and non-PM fiber versions.

The above capabilities make cladding power strippers essential parts in:

- High-power fiber laser and amplifier systems.

- Applications requiring cladding-mode-free beam delivery.

- ASE stripping in amplifiers.

- Advanced uses in research, telecommunications, biomedicine, and more.

As fiber laser technology continues to advance to new frontiers, cladding power strippers will play a crucial role in building higher power, more efficient, and more reliable systems.

Cladding power strippers absorb and eliminate excess unusable pump light in the inner cladding of high-power fiber lasers. Their unique ability to strip away unwanted modes makes cladding power strippers necessary to fully use the potential of high-power fiber laser systems

Leave A Comment