When comes to a fiber laser, it is widely utilized in various fields like medicine, the military, and machinery. Since the development of fiber lasers, higher-power lasers have gotten more and more popular and desirable. Nonetheless, lasers that have a power level of kilowatt or more have been raised; there could be plenty of issues with the enhanced power.

One of the most crucial issues that must be solved is- how to strip non-essential pump light prior to laser emit out from various devices. With the development in the early years, individuals have built some techniques to get rid of this problem.

Having said that, however, the developed methods also have loads of drawbacks like too small stripping area to achieve high power light emission and inadmissibility of the technology (innovation) for volume production. The glue method is the first and the foremost way for stripping the non-essential light. One of the biggest advantages is the easy process. However, it also has a drawback i.e. glue cannot bear under-high temperatures in the range of 60°C to 70°C. s

To get rid of this issue, individuals have made lots of attempts for a couple of years by raising the bearing temperature of glue or forced cooling. However, till today, there is no apt solution. In fiber lasers, the superfluous pump light is smoggy and has contributions from the pump light that is not fully soaked by gain fiber and from high order laser due to misalignment components.

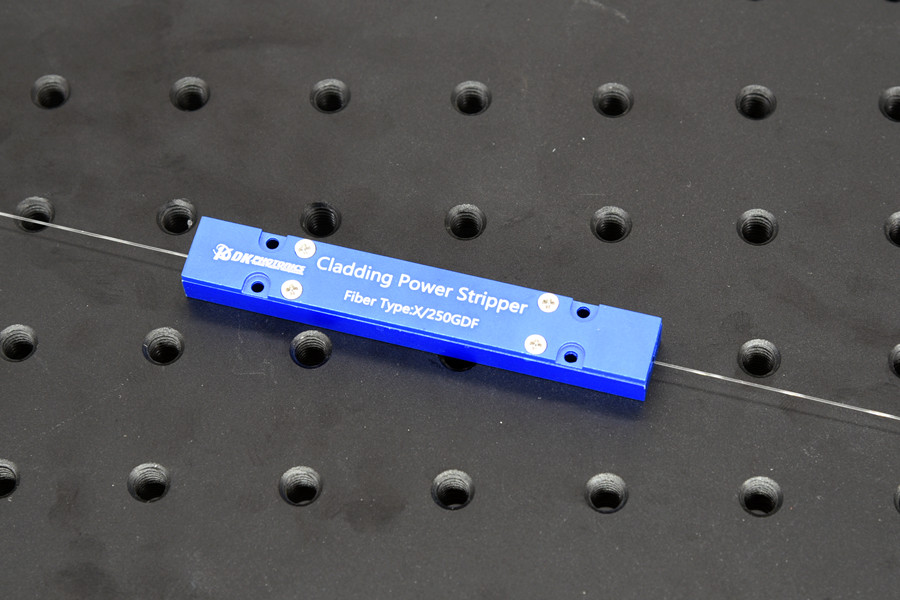

To properly strip the inner cladding light and get higher stripping power and uniform heat distribution, we have utilized optimized high index glue to fabricate the cladding power stripper. The common idea is to better the heat distribution in the cladding power stripper by handling the structure of the double-clad fiber. The particular method is to rotate the cutting area so the light of the pump can emit perfectly, and the glue will have under controlled working temperature. Experiments and FE stimulation are managed to study the thermal effect of cladding power strippers.

The outcomes display that the highest stable operating temp is 50.0°C when the cladding power is 132 W, and the temperature of the cladding power stripper increases linearly with the increase of the stripping power. There is no overheating point in the stripper in the test indicating that the proposed technique is applicable for kilowatt level fibers lasers.

The experimental outcomes are regular with FE simulations, verifying the authenticity of the stimulation model and parameter. As the working temperature is much lower than 60°C, the outcomes show that such a cladding power stripper structure is dependable and its properties can be easily described by simulations.

For more information, contact us hassle-freely.

Leave A Comment