Before you know about inline polarizers, you should understand what polarization is. It is the direction in which the electric field of a light wave oscillates.

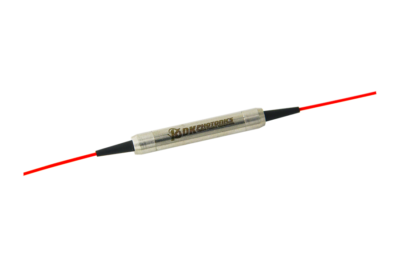

An inline polarizer uses selective absorption, refraction, or transmission to turn unpolarized light into polarized light. It is a device that transmits light waves along one axis and absorbs them along the other. The inline polarizers allow the transmission of only one polarization state. In this, the transmitting and absorbing axes are oriented at 90 degrees to each other.

The different methods to produce linearly polarized light are:

- Double refraction or birefringent polarizers

- Reflection polarizers

- Dichroic absorptive polarizers

What are the specifications of inline polarizers?

850nm. 1550nm, 1310nm, 1064nm, and 980 nm inline polarizers are some of the inline polarizer types. Before choosing one among them, you should consider several key specifications.

Extinction ratio– It’s a ratio that defines the ratio between the transmittance of the desired polarization direction and the undesired orthogonal polarization direction. It’s the power of a plane-polarized beam that is transmitted through a polarizer.

In this, the polarizing axis is parallel to the beam’s plane. But, with the transmitted power, the polarizer’s axis is perpendicular to the beam’s plane. The extinction ratio is also referred to as the contrast ratio.

Transmittance– It’s the percentage of light, passing through the polarizer. When the light is polarized, it goes through the polarizer at 100% transmittance. But, if the polarizers are not perfect, the light will never reach 100% transmittance.

For maximum transmittance, a polarizer is placed to ensure the polarization axis and incoming light are parallel. If the axis and incoming light are perpendiculars, the transmittance is low.

Clear aperture- It describes the surface area of an optical filter, free of any defects or obstructions. As the boundary of the clear aperture is often metal or opaque material, it doesn’t restrict the overall aperture of the microscope. Most importantly, there is no leakage of unfiltered light around the edge.

Diameter and thickness– Diameter is one specification that you cannot miss at any cost when choosing the right inline polarizer. The diameter sizing depends on how the polarizer is manufactured.

Regarding thickness, it is the retardation plates used in the polarizer devices.

Beam deviation– It’s the deviation of the polarized beam from normal. It is calculated by observing the difference in angle of an incoming beam to a transmitted, reflected, or refracted through an optic.

What are the applications of inline polarizers?

The inline polarizers are widely applied in the electronics, photographic, scientific and industrial fields. But, keeping these applications aside, the largest use of inline polarizers is in liquid crystal displays or LCDs. It’s just that the device has to be placed properly when used.

Other than this, the inline polarizers are also popular in camera filters, sunglasses, and a machine vision system. This is when flare reduction is required. With the right placement, the brightness and intensity of a light source are controlled.

Inline polarizers, including 980nm inline polarizers and others, are very important. So, you should look for a reputable manufacturer or supplier for the same.

Leave A Comment